You may wonder about the practicality of 3D printing beyond just creating trinkets or prototypes. However, the applications of this technology are far-reaching and impactful. From revolutionizing healthcare with custom prosthetics to enhancing automotive design processes, 3D printing is changing the way industries operate.

But these are just the tip of the iceberg. Stay tuned to discover how this innovative technology is reshaping various sectors and pushing the boundaries of what is possible.

Healthcare Innovations

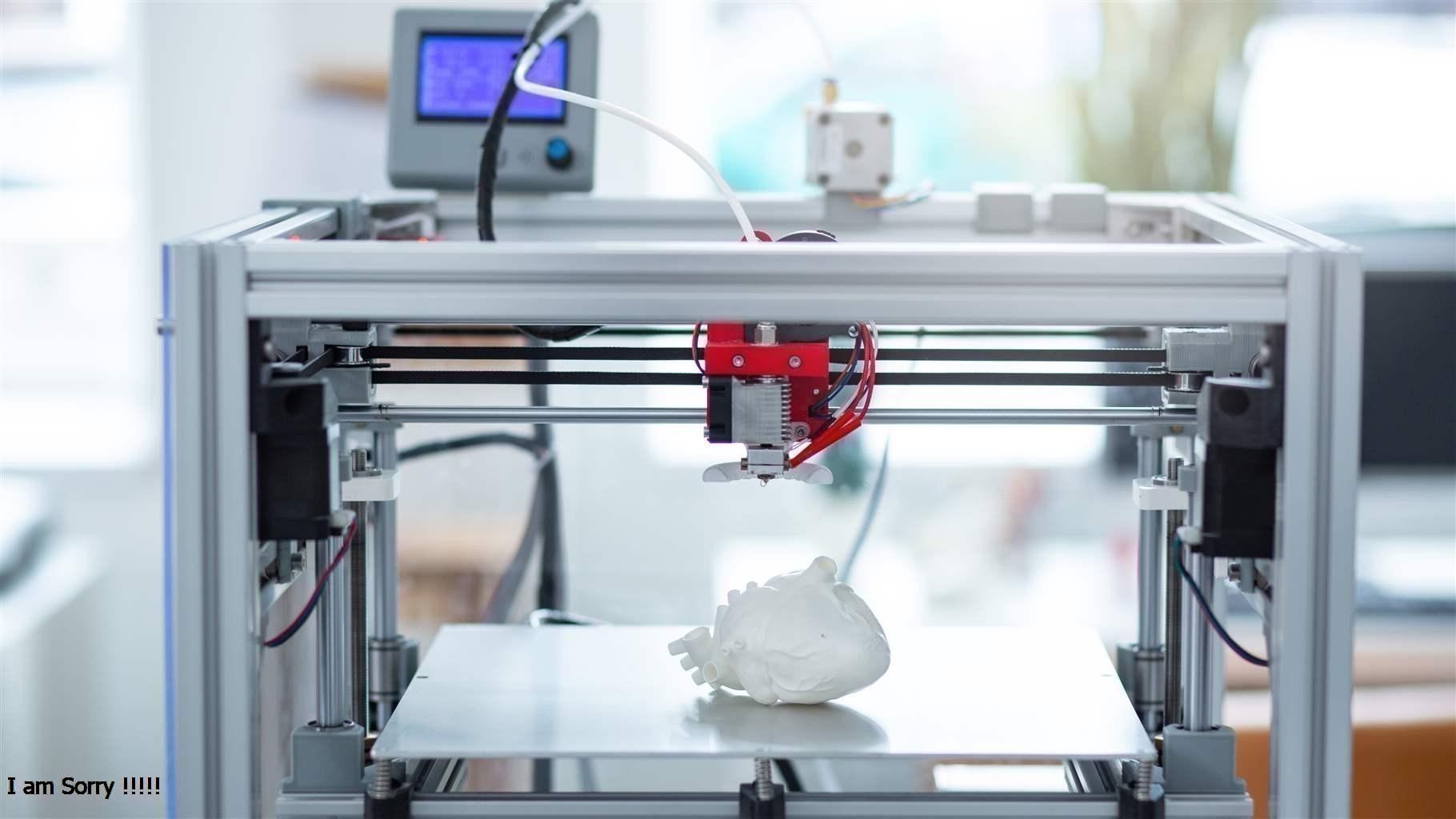

In recent years, 3D printing has revolutionized healthcare by enabling the creation of personalized medical devices and implants. This technology allows for the fabrication of intricate structures that match the specific anatomy of individual patients, leading to better treatment outcomes. One significant application is the production of custom prosthetics tailored to the unique requirements of each patient. These prosthetics can be more comfortable, functional, and aesthetically pleasing compared to traditional mass-produced options.

Moreover, 3D printing is instrumental in the development of patient-specific surgical guides. These guides assist surgeons in accurately performing complex procedures by outlining the precise locations for incisions and implants based on the patient’s anatomy. This level of customization enhances the precision and success rates of surgeries while reducing operation times and potential complications.

Additionally, the pharmaceutical industry benefits from 3D printing technology through the production of personalized drug doses. This innovation allows for the creation of medicines tailored to individual patients, optimizing treatment effectiveness and minimizing adverse reactions. The versatility and precision of 3D printing continue to drive advancements in healthcare, promising a future where personalized medicine is the norm.

Automotive Advancements

Leveraging cutting-edge technologies, automotive advancements have transformed the industry’s landscape with innovative solutions and enhanced performance capabilities. 3D printing has revolutionized the automotive sector by enabling rapid prototyping of complex designs, reducing time-to-market for new vehicle models. Additive manufacturing allows for the creation of intricate parts with improved strength-to-weight ratios, enhancing overall vehicle performance.

One key application of 3D printing in automotive advancements is the production of lightweight components such as engine parts, interior panels, and custom accessories. These components, often made from advanced materials like carbon fiber composites, contribute to increased fuel efficiency and overall vehicle durability. Moreover, additive manufacturing facilitates the customization of parts based on specific vehicle requirements, leading to more personalized and tailored automotive solutions.

Additionally, 3D printing technology is utilized in the development of concept cars and prototypes, allowing designers to quickly iterate on designs and test new ideas efficiently. This iterative process helps streamline the product development cycle and fosters innovation within the automotive industry.

Architectural Solutions

The integration of 3D printing technology in architectural solutions allows for the creation of intricate and customized building components with enhanced efficiency and precision. Architects and designers can now leverage 3D printing to fabricate complex geometries that were previously challenging to produce using traditional methods. This technology enables the rapid prototyping of architectural models, facilitating the exploration of innovative design concepts and enhancing communication with clients.

Moreover, 3D printing facilitates the production of custom architectural elements, such as ornamental facades, detailed moldings, and unique structural components. By utilizing advanced materials like reinforced concrete or composite filaments, architects can achieve both aesthetic appeal and structural integrity in their designs. The ability to manufacture bespoke building parts on-demand not only streamlines the construction process but also reduces material waste, making 3D printing a sustainable solution for architectural projects.

Incorporating 3D printing into architectural workflows empowers professionals to push the boundaries of design, create more sustainable structures, and deliver tailored solutions to meet the evolving needs of modern construction projects.

Industrial Manufacturing

With its ability to fabricate intricate components efficiently, 3D printing has revolutionized industrial manufacturing processes. In industrial settings, 3D printing is used for rapid prototyping, allowing companies to quickly test and iterate designs before mass production. This technology enables the creation of complex geometries that traditional manufacturing methods struggle to produce, leading to improved product performance and reduced material waste.

One key advantage of 3D printing in industrial manufacturing is the ability to customize products at scale. By leveraging additive manufacturing techniques, companies can tailor products to meet specific customer requirements without incurring significant additional costs. This personalized approach enhances customer satisfaction and opens up new business opportunities.

Moreover, 3D printing facilitates on-demand production, reducing inventory costs and streamlining supply chains. Manufacturers can produce spare parts, tools, and components as needed, eliminating the need for large warehouses and long lead times. This just-in-time manufacturing approach increases operational efficiency and flexibility in responding to market demands.

Educational Tools

When considering educational tools, 3D printing technology offers a versatile and innovative approach to enhance learning experiences. The ability to create physical models of complex concepts allows for tactile and visual learning, benefiting students across various subjects. In science, intricate anatomical models can aid in biology lessons, enabling students to understand the human body in a hands-on way. Similarly, in mathematics, geometric shapes can be printed to demonstrate spatial reasoning and problem-solving.

Moreover, 3D printing can be used to create historical artifacts for history lessons, bringing ancient objects to life in the classroom. This immersive experience helps students engage with the past in a tangible manner. Additionally, the technology can be leveraged to prototype designs in engineering classes, fostering creativity and practical skills. By using 3D printing as an educational tool, students can develop a deeper understanding of abstract concepts and improve their critical thinking abilities through interactive learning experiences.