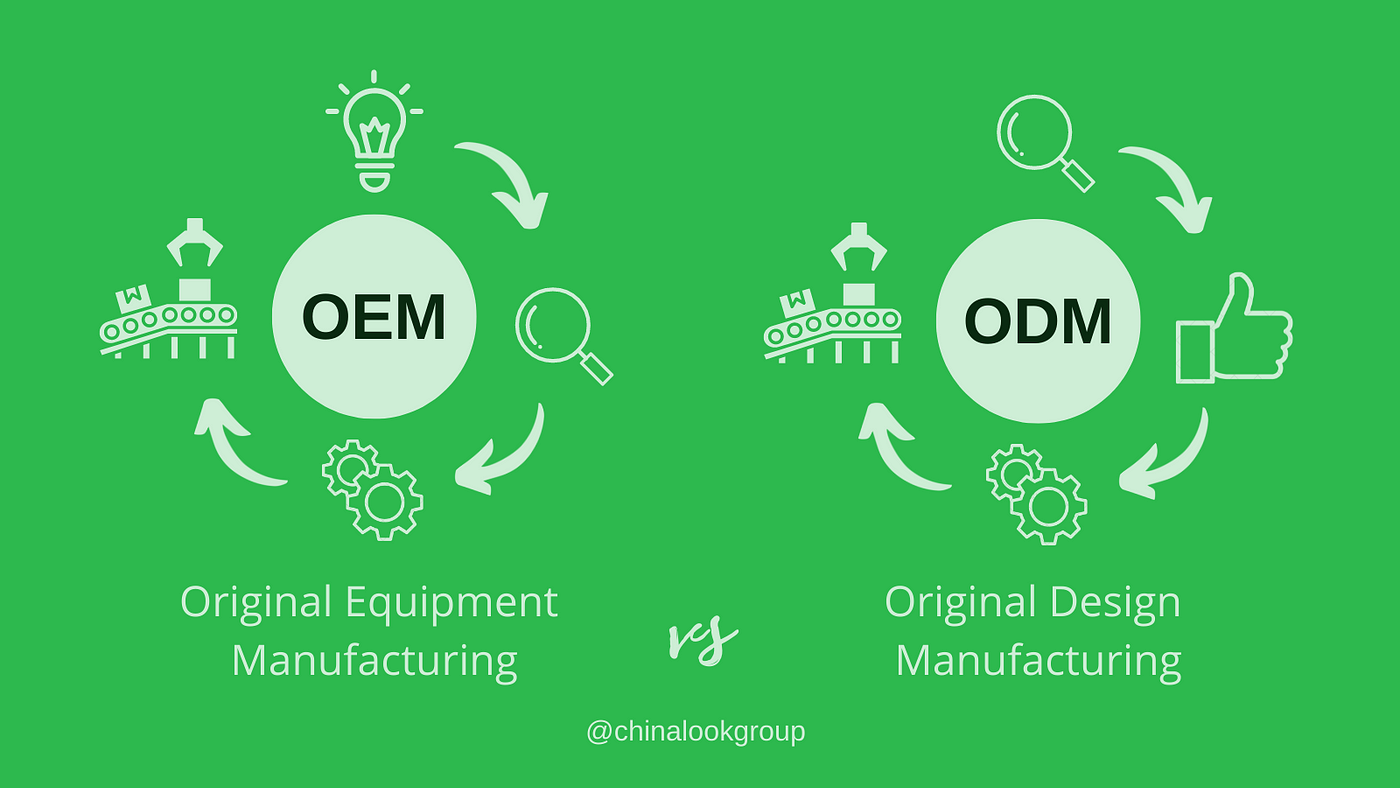

In the realm of manufacturing, the terms OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) are frequently used but often misunderstood. Both play crucial roles in bringing products to market, but their approaches and responsibilities vary significantly. Let’s delve into the distinctions between OEM vs ODM to gain a clearer understanding of their roles and contributions to the manufacturing ecosystem.

Defining OEM (Original Equipment Manufacturer):

An OEM, or Original Equipment Manufacturer, is a company that designs and produces components or products that are marketed and sold by another company under their brand name. In simpler terms, OEMs focus on manufacturing products based on the specifications and requirements provided by the brand or company that sells them.

Key Characteristics of OEM:

- Manufacturing Expertise: OEMs excel in manufacturing processes and have the infrastructure, expertise, and resources to produce goods efficiently and at scale.

- Customization Capability: They often offer customization options to tailor products according to the brand’s specifications, allowing for branding, packaging, and minor modifications to meet specific requirements.

- Brand Outsourcing: OEMs typically remain behind the scenes, with their branding and identity taking a backseat to the brand they manufacture for. Consumers may not be aware of the OEM’s involvement in the production process.

Understanding ODM (Original Design Manufacturer):

Conversely, an ODM, or Original Design Manufacturer, is a company that designs and manufactures products based on their own specifications, branding, and intellectual property. ODMs develop products independently and then sell them to other companies who market and distribute the products under their brand names.

Key Characteristics of ODM:

- Design Expertise: ODMs specialize in product design and development, leveraging their creativity, innovation, and engineering capabilities to conceptualize and create new products from scratch.

- White-Label Products: ODMs offer ready-made products that can be branded and marketed by other companies without significant modifications. These products are often referred to as “white-label” or “private-label” goods.

- Brand Flexibility: ODMs provide flexibility to companies by offering a range of pre-designed products that can be customized to some extent to align with the brand’s identity and requirements.

Comparing OEM and ODM:

While both OEM vs ODM contribute to the manufacturing ecosystem, their roles and responsibilities differ significantly:

- Ownership of Design: OEMs manufacture products based on designs provided by the brand, whereas ODMs independently conceive, design, and manufacture products based on their own specifications and creativity.

- Brand Visibility: OEMs operate behind the scenes, with the brand taking center stage in marketing and selling the products. In contrast, ODMs may have their branding on products, especially if they are selling directly to consumers under their own label.

- Customization vs. Creativity: OEMs focus on customization and production efficiency, while ODMs prioritize innovation, creativity, and product differentiation to appeal to a broader market.

Conclusion:

In summary, OEM vs ODM play distinct yet complementary roles in the manufacturing landscape. OEMs excel in producing goods based on the specifications provided by brands, offering customization and scalability, while ODMs specialize in designing and manufacturing products independently, providing ready-made solutions that can be branded and marketed by other companies. Understanding the differences between OEM and ODM is essential for companies seeking manufacturing partnerships and navigating the complexities of the global supply chain.